- Home

- Products

- Metal Cutting Solutions

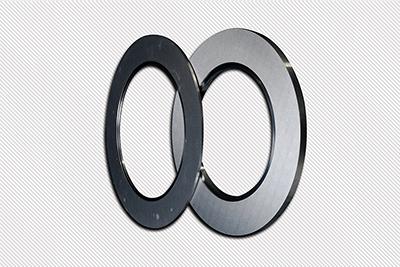

- Circular Metal Slitter Blade & Rotary Slitter Blade

Circular Metal Slitter Blade & Rotary Slitter Blade

Material introduction

Raw materials are both the most fundamental and most important link in blade production. The circular metal slitter blades are mainly made of 6CrW2Si, SKD-11 (D2), LD (7CrSiMnMoV) , H13, HMY, (HSS) SKH-51, M2, imported materials etc. Seton has developed a new type of material SLD processed by special heat treatment, featuring higher abrasion resistance and good ductility. Thus the problems that blade needs to sharpen frequently and its edge easily breaks due to poor abrasion resistance, which is caused by high strength and high thickness slitting materials, are solved.

Application

The circular metal slitter blade is mainly used in slitting lines to unwind metal coils into metal strips, which can slit silicon steel sheets, hot and cold rolled stainless steel coils, galvanized iron, hot and cold rolled strips, aluminum coils, copper coils, rubber tires, etc.

| Hardness | HRC 55-70 |

| Tolerance of external diameter | ±0.01mm |

| Tolerance of internal diameter | 0.01-0.04 |

| Thickness | ±0.001mm |

| Flatness | ≦0.003 |

| Parallelism | ≦0.002 |

| Concentricity | ≦0.02 |

| Surface roughness | Ra 0.1u |

Features

The circular metal slitter blade is the most important link in slitter tool apron. The main problems customers encounter during use are the poor abrasion and edge crack in blade. Seton's slitter blades have the following features, therefore reducing the blade sharpening frequency.

- The blades of Seton are made of high quality raw materials and manufactured by forging and advanced vacuum heat treatment technology, which have high hardness and stability, and the abrasion resistance is remarkably improved.

- The blade surface is processed with precision surface grinder and special grinding technology. After strict quality test, all finished products are guaranteed with a flatness of within 0.0003mm, a thickness tolerance of ±0.001mm, and a concentricity of within 0.02.

Custom made

According to different slitting capabilities, slitting materials and shaft diameters, the custom range is as follows:

| Outer diameter custom range | 70mm~1050mm |

| Slitting thickness | 0.1mm~16mm |

| Tensile strength of slitting materials | ≤1200 N/mm² |

| Slitting speed | 60m/min~150m/min |

Matching machines

TCSF, GEORG, Butech Bliss, CAMU etc.

Related Products

metal shear blade, shear knives, industrial metal cutter, machine knives

Jiangsu Seton Industrial Technology Co., Ltd.

Add.: No.99, Furong Mid Three Road, Xishan Economic Development Zone, Wuxi

Tel.: +86-510-83792887

Fax: +86-510-83632182